Learn more about our

AQUAPONICS SYSTEMS

and find your perfect solution

Aquaponics Complete Systems

Aquaponics System Components

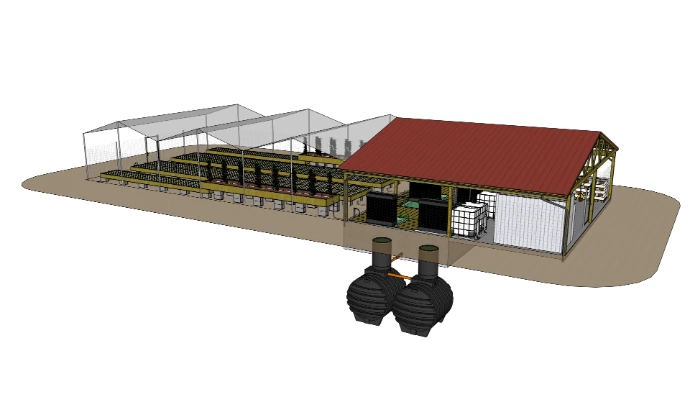

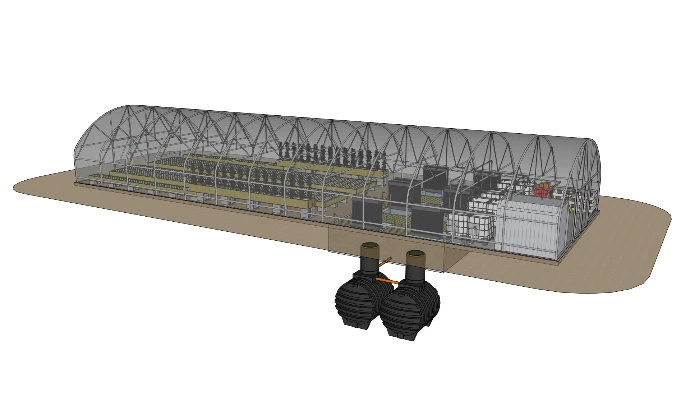

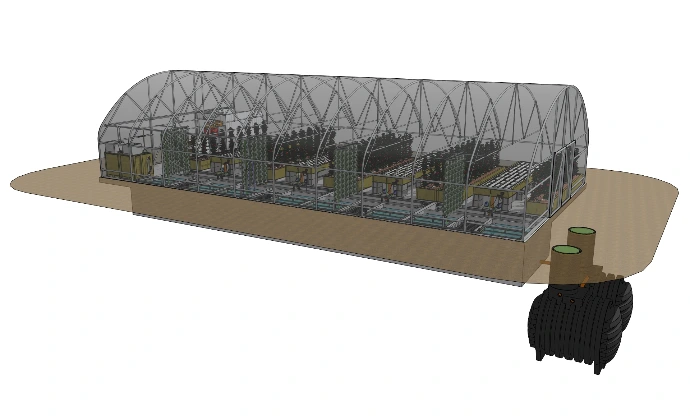

Standard

HC | Hot Climate

Concrete Tanks

no heating and no isolated building is needed.

The system is designed for the usage in the hot areas of the world. The aquaculture and the hydroculture section are built without housing.

A roof and a shading net protect the system from intense sun light and heavy rain. A fence is built to keep predators away.

Space Requirement:

Aquaculture section: 11,3 m x 12,2 m

Hydroculture section: 20,0 m x 12,2 m

Total area: 31,3 m x 12,2 m

The length of the hydroculture gives you an annual production capacity of 36,500 salads at year-round production and can be adjust to optimize production or space requirements.

Production Capacity Fish:

The aquaculture section of the system consists of optimized filter tanks,

8 growout tanks (total 23,7 m³ water) and

8 juvenile tanks (total 7,7 m³ water)

Depending on the fish you want to produce, the maximum production capacity varies considerably:

African Catfish (280 kg/m³ density): 26,9 to p.a.

Tilapia (100 kg/m³ density): 6,8 to p.a.

Material Costs:

The material costs to build this system can be estimated between 200,000 and 250,000 Euros based on prices achievable in middle Europe.

As many customers build the system themselves, labor is not included in this cost estimation.

Annual system input/output:

Fingerlings: 14.211 pcs.

Fish feed: 24.376 kg (for African Catfish)

Freshwater: 747 m³

Electricity: 27,4 MWh

Sludge water: 618 m³

Additives: Small amounts for PH management

Construction Method:

The filter system and the growout tanks are made of concrete and typically are sunk into the ground. The juvenile tanks are build of light material.

Depending on availability, the shading structure and the roof can be made from wooden or metal profiles.

The floor of the hydroculture section can be made of concrete or less solid materials like gravel or laying plates. The hydroponic beds are usually made of wood and foil.

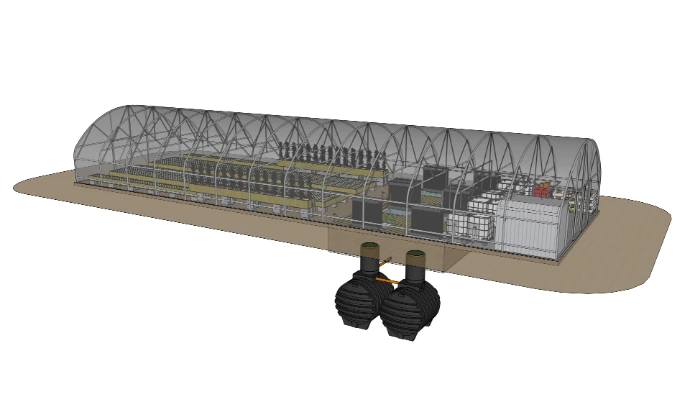

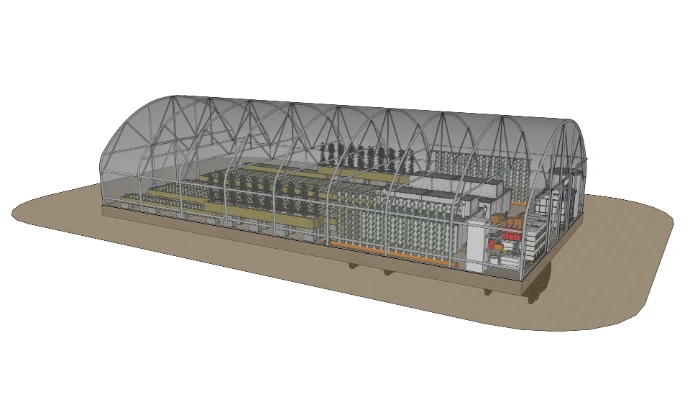

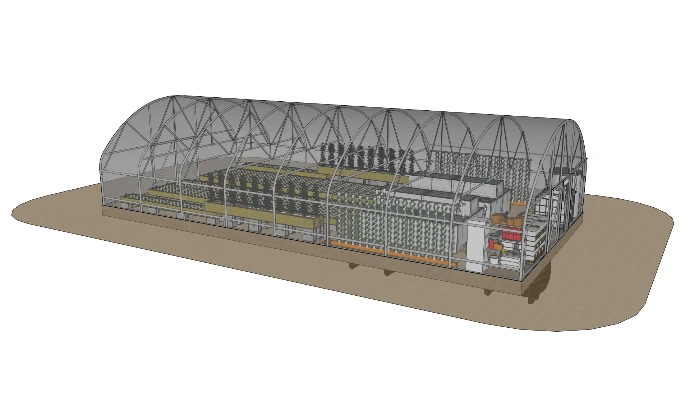

Standard

MC | Moderate Climate

Concrete Tanks

The system is designed for the usage in areas with moderate tempered climate and for customers in cold areas with cheap heating capacity such as biogas plant operators.

The whole system is located inside a greenhouse with nominal width of 10 m. The heating is not part of the construction plan.

Space Requirement:

Aquaculture section: 12,1 m x 10,2 m

Hydroculture section: 20,2 m x 10,2 m

Total area: 32,3 m x 10,2 m

The length of the hydroculture gives you an annual production capacity of 25,100 salads

(10 month production) and can be adjust to optimize production or space requirements.

Production Capacity Fish:

The aquaculture section of the system consists of optimized filter tanks,

8 growout tanks (total 23,3 m³ water) and

8 juvenile tanks (total 7,6 m³ water)

Depending on the fish you want to produce, the maximum production capacity varies considerably:

African Catfish (280 kg/m³ density): 26.5 to p.a.

Tilapia (100 kg/m³ density): 6.7 to p.a.

Material Costs:

The material costs to build this system can be estimated between 250,000 and 300,000 Euros based on prices achievable in middle Europe.

As many customers build the system themselves, labor is not included in this cost estimation.

Annual system input/output:

Fingerlings: 13.984 pcs.

Fish feed: 23.977 kg (for African Catfish)

Freshwater: 702 m³

Electricity: 27,4 MWh (excl. heating)

Sludge water: 595 m³

Additives: Small amounts for PH management

Construction Method:

The filter system and the fish tanks are made of concrete and typically are sunk into the ground. The juvenile tanks are build of light material.

The greenhouse is typically made of a steel structure with isolated foil. As an alternative glass greenhouse can be used.

The floor of the hydroculture section can be made of concrete or less solid materials like gravel or laying plates. The hydroponic beds are usually made of wood and foil.

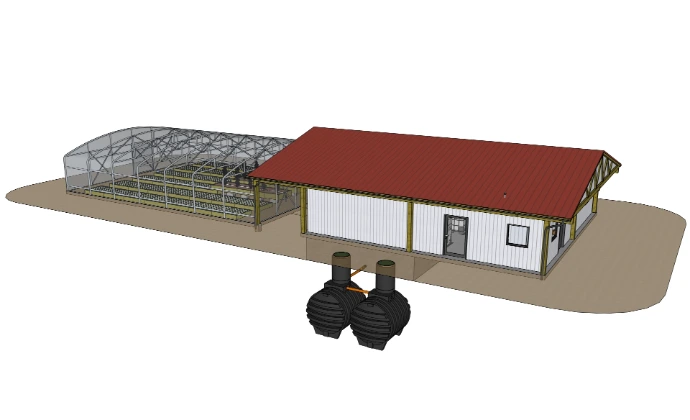

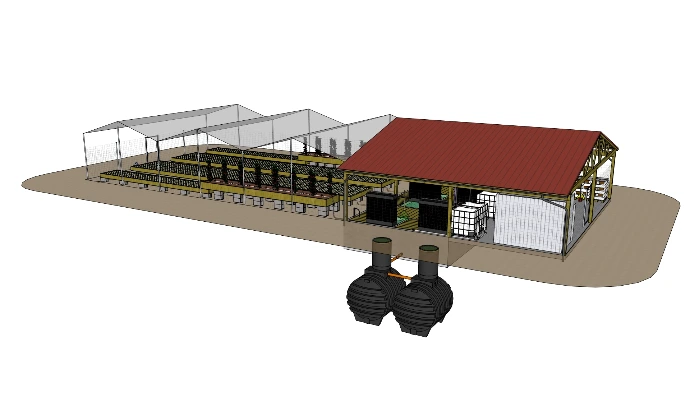

Standard

CC | Cold Climate

Concrete Tanks

focus lays on production yield. Heating is required.

The system is designed for the usage areas where the winters are cold and long.

A isolated building reduces the energy loss and by that minimizes the heating costs so that even in winter the production of warm water fish is economically reasonable. The heating is not part of the construction plan.

Space Requirement:

Aquaculture section: 13,0 m x 12,5 m

Hydroculture section: 20,2 m x 12,2 m

Total area: 33,2 m x 12,5 m

The length of the hydroculture gives you an annual production capacity of 27,400 salads (9 month production) and can be adjust to optimize production or space requirements.

Production Capacity Fish:

The aquaculture section of the system consists of optimized filter tanks,

8 growout tanks (total 23,7 m³ water) and

8 juvenile tanks (total 7,7 m³ water)

Depending on the fish you want to produce, the maximum production capacity varies considerably:

African Catfish (280 kg/m³ density): 26,9 to p.a.

Tilapia (100 kg/m³ density): 6,8 to p.a.

Material Costs:

The material costs to build this system can be estimated between 300,000 and 350,000 Euros based on prices achievable in middle Europe.

As many customers build the system themselves, labor is not included in this cost estimation.

Annual system input/output:

Fingerlings: 14.211 pcs.

Fish feed: 24.376 kg (for African Catfish)

Freshwater: 747 m³

Electricity: 27,4 MWh (excl. heating)

Sludge water: 618 m³

Additives: Small amounts for PH management

Construction Method:

The filter system and the growout tanks are made of concrete and typically are sunk into the ground. The juvenile tanks are build of light material.

The building usually consists of a wooden structure with sandwich panel walls. Alternatively bricks or concrete can be used.

The floor of the hydroculture section can be made of concrete or less solid materials like gravel or laying plates. The hydroponic beds are usually made of wood and foil.

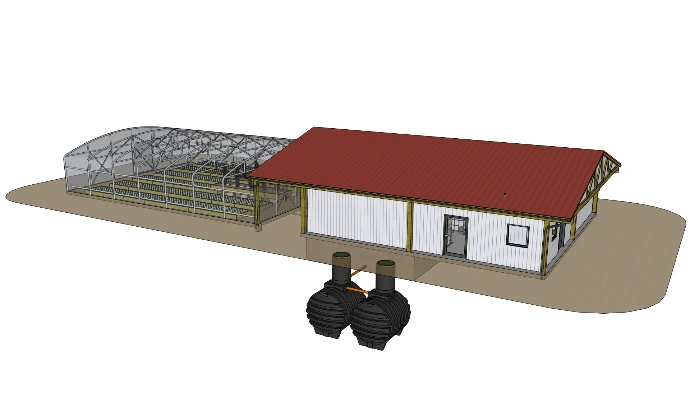

Standard

NCE | "Paradise"

Concrete Tanks

The system is designed for the usage in areas with moderate or cold climate.

Our "beauty" is an aquaponics system for customers which are willing to accept a slightly lower production output in favor of a nice system setup. The heating is not part of the construction plan.

Space Requirement:

Aquaculture section: 20,2 m x 3,7 m

Hydroculture section: 20,2 m x 6,5 m

Total area: 20,2 m x 10,2 m

The size of the hydroculture gives you an annual production capacity of 14,400 salads

(10 month production). It can only be adjust by using a wider greenhouse.

Production Capacity Fish:

The aquaculture section of the system consists of optimized filter tanks,

8 growout tanks (total 28,1 m³ water) and

8 suspended juvenile nets.

Depending on the fish you want to produce, the maximum production capacity varies considerably:

African Catfish (280 kg/m³ density): 21.5 to p.a.

Tilapia (100 kg/m³ density): 6.2 to p.a.

Material Costs:

The material costs to build this system can be estimated between 250,000 and 300,000 Euros based on prices achievable in middle Europe.

As many customers build the system themselves, labor is not included in this cost estimation.

Annual system input/output:

Fingerlings: 11.388 pcs.

Fish feed: 19.500 kg (for African Catfish)

Freshwater: 662m³

Electricity: 15,2 MWh (excl. heating)

Sludge water: 596 m³

Additives: Small amounts for PH management

Construction Method:

The filter system and the fish tanks are made of concrete and typically are sunk into the ground. The juvenile net float in the growout tank.

The greenhouse is typically made of a steel structure with isolated foil. As an alternative glass greenhouse can be used.

The floor of the hydroculture section can be made of concrete or less solid materials like gravel or laying plates. The hydroponic beds are usually made of wood and foil.

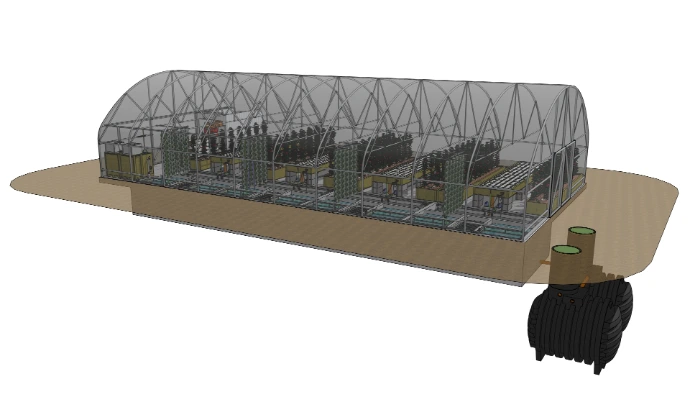

Standard

MOD | Ease-In

Above ground DIY Tanks

The system is designed for the usage in areas with moderate or cold climate.

The system consists of 4 isolated modules that are coupled with each other and the hydroculture beds. Each module can also be operated alone. The heating is not part of the construction plan.

Space Requirement:

Aquaculture section: 8,2 m x 10,2 m

Hydroculture section: 12,0 m x 12,2 m

Total area: 20,2 m x 10,2 m

The length of the hydroculture gives you an annual production capacity of 27,440 salads (10 month production). It can be adjust to optimize production or space requirements.

Production Capacity Fish:

The 4 aquaculture modules of the system consists of optimized filter tanks,

4 growout tanks (total 7,9 m³ water) and

4 juvenile tanks (total 2,6 m³ water)

Depending on the fish you want to produce, the maximum production capacity varies considerably:

African Catfish (280 kg/m³ density): 8,9 to p.a.

Tilapia (100 kg/m³ density): 2,2 to p.a.

Material Costs:

The material costs to build this system can be estimated between 80,000 and 100,000 Euros based on prices achievable in middle Europe.

As many customers build the system themselves, labor is not included in this cost estimation.

Annual system input/output:

Fingerlings: 4.721 pcs.

Fish feed: 8.118 kg (for African Catfish)

Freshwater: 284m³

Electricity: 6,4 MWh

Sludge water: 219 m³

Additives: Small amounts for PH management

Construction Method:

The filter system, the growout and the juvenile tanks are made of wood with with inserted liner bags. The coupling tank is an underground tank.

The greenhouse is typically made of a steel structure with isolated foil. As an alternative glass greenhouse can be used.

The floor of the hydroculture section can be made of concrete or less solid materials like gravel or laying plates. The hydroponic beds are usually made of wood and foil.

Individual

IND | Customized

Adapted to your needs

to fulfill your requirements .

Tailored to your needs.

Space Requirement:

Tailored to your needs.

Production Capacity Fish:

Tailored to your needs.

Material Costs:

Depending on your needs.

Annual system input/output:

Tailored to your needs.

Construction Method:

Tailored to your needs.

To ensure that the tailored system can be implemented in line with your expectations, we recommend booking a video conference with one of our experts in advance.

During this session, you will have the opportunity to discuss everything in detail, including:

- your business ideas and objectives,

- the available facilities and land,

- the location of the required infrastructure,

- the fish and plants to be produced, and

- any additional questions you may have.

If you have already clarified the feasibility of the system, you can of course proceed directly to the shop and commission the customized planning of your system.

WHAT IS A PROJECT CONCEPT ?

The Project Concept is a central component of the first step toward your aquaponics system. In this phase of the Feasibility Study, the building authority, the food safety authority, the water authority, and others are brought on board. For this purpose, you need professional documents that describe the system’s functionality, the project scope, and the system’s inputs and outputs.

Of course, the Project Concept can also be used in discussions with banks to demonstrate your well-founded approach to your aquaponics project.

Our company specializes in consulting, product development, and customer support. We tailor our services to fit the unique needs of businesses across various sectors, helping them grow and succeed in a competitive market.

Our project concepts consist of an overview plan with a description of the main components, elevation views with the most important dimensions, a site plan, and the most relevant technical specifications.

In addition, there is a separate facts document that explains the functional principles and general structure of aquaponics and contains all data relevant for the authorities.

The standard Project Concepts are made available for download after checkout in the online shop. The documents are provided in PDF format, which you can forward to the authorities or print as needed.

For individual projects, the Project Concepts are created after your order and then sent electronically. For organizational reasons, we do not provide or ship paper documents.

For more extensive changes, or if your project needs to be tailored precisely to your requirements, we recommend our individual planning services.

All of them are optimized for operation as small to medium-sized production facilities.

For this reason, we developed documents that make it easier to discuss your project with the stakeholders (authorities, banks,...) and get their permission to move on.

The design of the aquaculture section is optimized for rearing African Catfish. This species we see most suitable for production of high quality fish and fillets in a RAS (Recirculating Aquaculture System).

This is due, on the one hand, to their very rapid growth and robustness, as the fish are able to breathe air at the water surface when oxygen concentrations are low. On the other hand, the firm and boneless meat is ideally suited for direct marketing, as it also appeals to customers who are not particularly fond of fish.

In addition to African catfish, other species such as tilapia, carp, and striped bass can also be raised successfully. However, the yields are significantly lower.

WHAT IS A CONSTRUCTION MANUAL ?

The Construction Manuals are highly detailed documents that enable you, as a skilled craftsman, to implement your aquaponics system either entirely on your own or with the support of local trades and contractors.

With the standard documents, you can implement the second process step—System Design—very quickly and move directly on to the third step, Construction. If you require a customized solution for your aquaponics system, we are ready to support you until your plan looks exactly the way you envision it.

- 3D Virtual Twin Views

Each system is created in detail as a 3D model to ensure ease of construction and optimal functionality. Beyond planning, the virtual twin provides a clear and intuitive way to visualize and communicate all aspects of the plant. - Step by Step Manual

The construction manual of over 100 pages is clearly structured and very detailed to guide you through the building of your system. From explaining the overall functionality and the system layout to the tasks of each individual system component and how to build it, everything is included. - Detailed 2D Plans

The dimensions of the various tanks and their associated inlets and outlets are crucial to the system’s later functionality. To ensure everything is built correctly, all relevant dimensions and diameters are shown and described in the plans. - Bill of Material (BOM)

The plan includes a detailed bill of materials listing all components required for construction. Based on this list, materials can be ordered and components can be procured. - Procurement Sourcing

When you purchase the construction plan, you receive access to our database, where you can find all the materials we have listed. These include detailed technical information, recommended suppliers, and current prices to support you in purchasing your materials.

The standard Construction Manuals are made available for download after checkout in the online shop. The documents are provided in PDF format, which you can print as needed.

For individual projects, the Construction Manual is created after your order and then sent electronically. For organizational reasons, we do not provide or ship paper documents.

It is not possible to personalize the standard Construction Manual.

If you choose to make modifications to the dimensions of the system elements or the described building instructions, you do so at your own risk. In that case, we cannot assume responsibility for the system’s functionality.

Based on our many years of experience and numerous successfully implemented customer projects, we have developed a number of standard aquaponics system types. These are adapted to different climatic conditions or optical / construction preferences. Find all available types below on the site.

All of them are optimized for operation as small to medium-sized production facilities.

We are convinced that the success of commercial aquaponics systems depends largely on keeping investment and operating costs, as well as the time required for operation and maintenance, as low as possible.

For this reason, our system concepts are based on smart physics instead of technical over-engineering. The designs and instructions are structured so that, with practical craftsmanship skills, the systems can be built by yourself or with the help of local companies. With the knowledge gained during the construction of the system you will be capable to do maintenance and repair when necessary.

The design of the aquaculture section is optimized for rearing African Catfish. This species we see most suitable for production of high quality fish and fillets in a RAS (Recirculating Aquaculture System).

This is due, on the one hand, to their very rapid growth and robustness, as the fish are able to breathe air at the water surface when oxygen concentrations are low. On the other hand, the firm and boneless meat is ideally suited for direct marketing, as it also appeals to customers who are not particularly fond of fish.

In addition to African catfish, other species such as tilapia, carp, and striped bass can also be raised successfully. However, the yields are significantly lower.

When designing the hydroponic section, we place particular emphasis on easy access for plant care and harvesting, as well as on the lowest possible susceptibility to malfunctions.

The purchase of a Construction Manual entitles you to use the documents for one (1) aquaponics system only. It is not permitted to share, resell, or use the documents for the construction of additional systems. All documents are marked and can be traced back to the purchaser. Any violation may result in civil legal consequences.